A2 ANALOG PROTOCOL

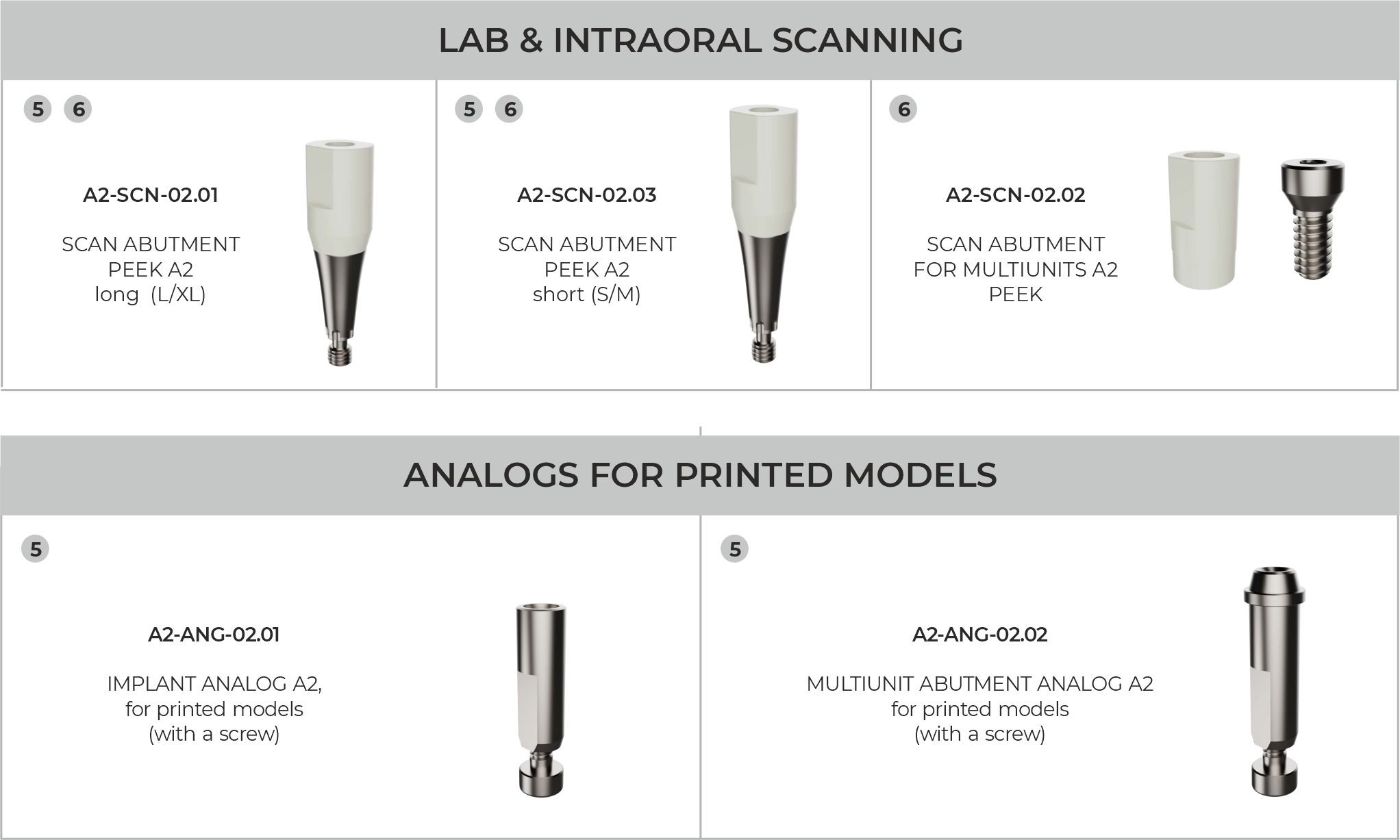

IMPLANT CLINICAL POSITION TRANSFER TO DENTAL LAB

A2 DIGITAL PROTOCOL

IMPLANT CLINICAL POSITION TRANSFER TO DENTAL LAB

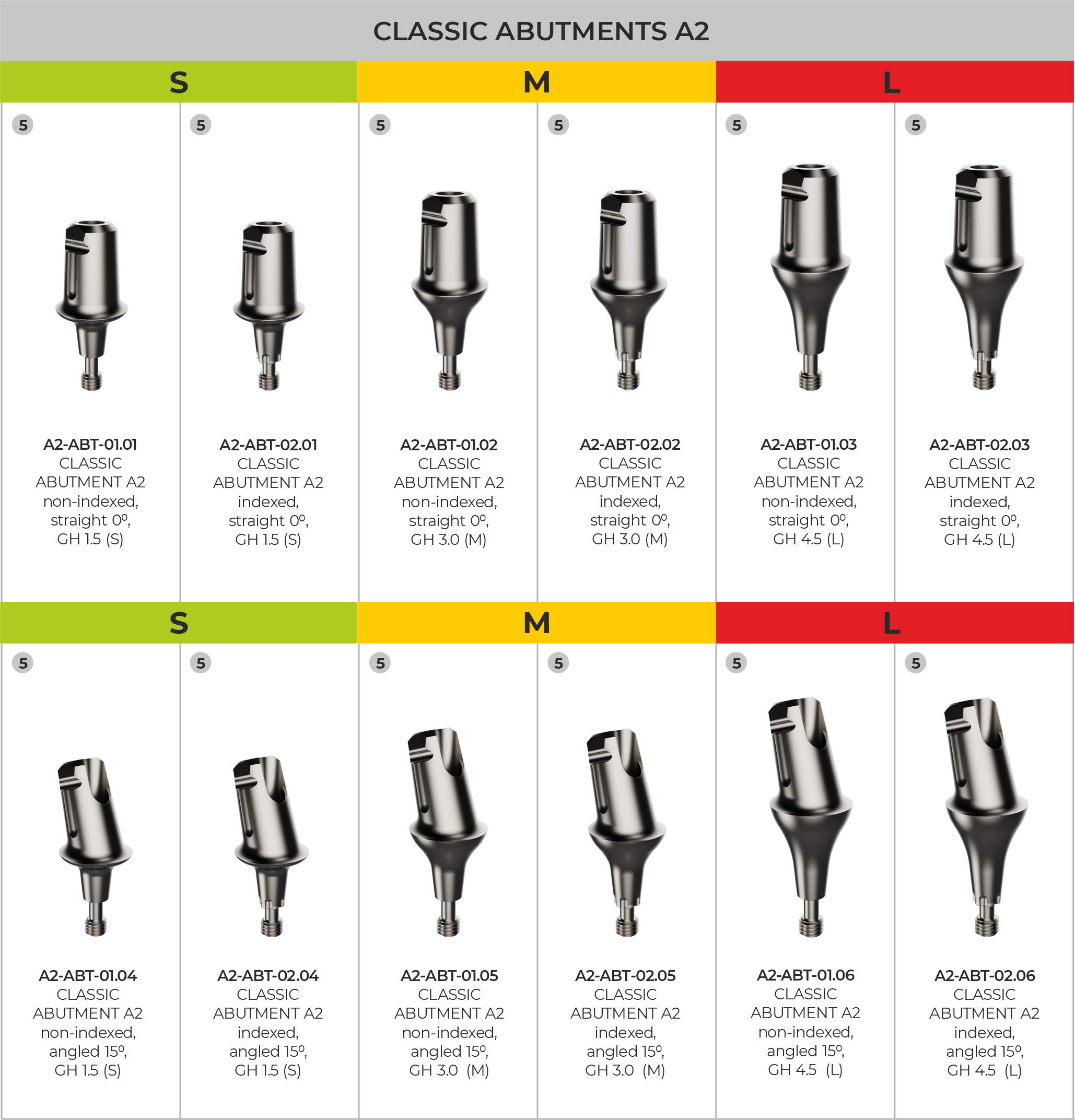

A2 CLASSIC ABUTMENTS

INDICATIONS for use : crowns and bridges with cement retention

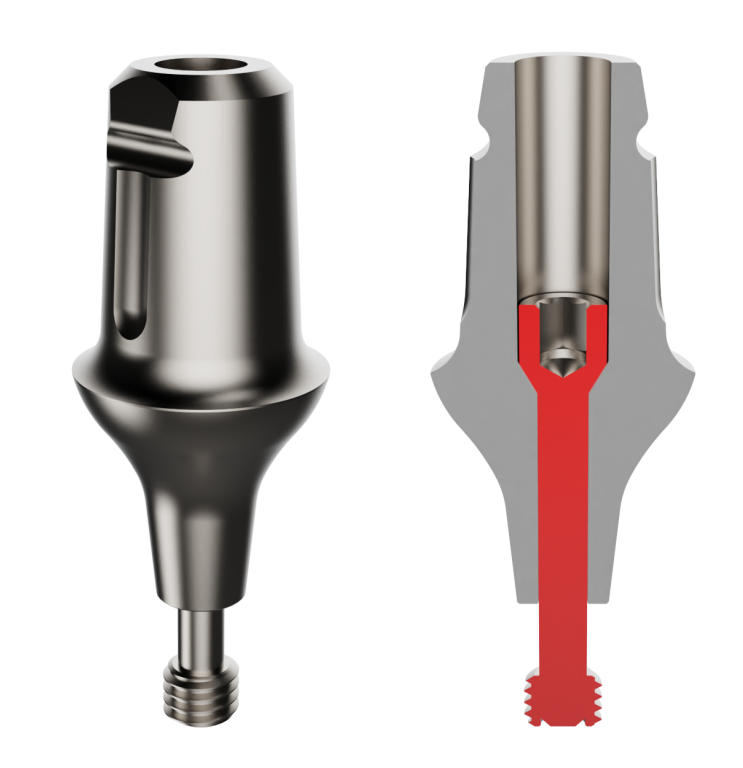

- are the most versatile and multifunctional suprastructures designed for crown and bridge fabrication.

- have an integrated screw to increase patient safety against aspiration: there is no need for placement and cannot fall out.

- offer a wide range of gingiva heights (S, M and L) an inclination angles (0° and 7.5°)

- can be customized to adapt their shape to a specific clinical situation.

- with an index can be easily seated in one of six positions.

- without an index, use a transfer key for proper positioning.

CAUTION: For reliable cement retention, the shortening should not be less than 4 mm.

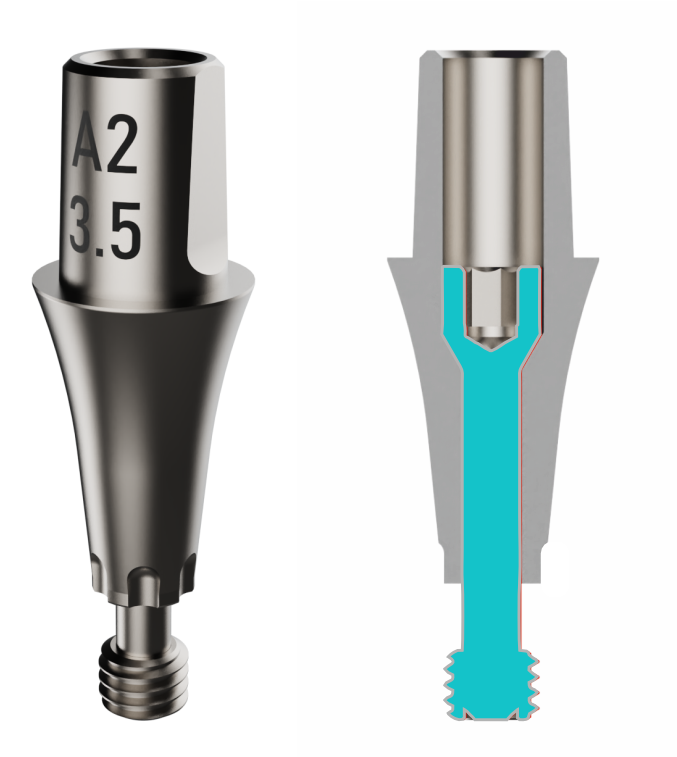

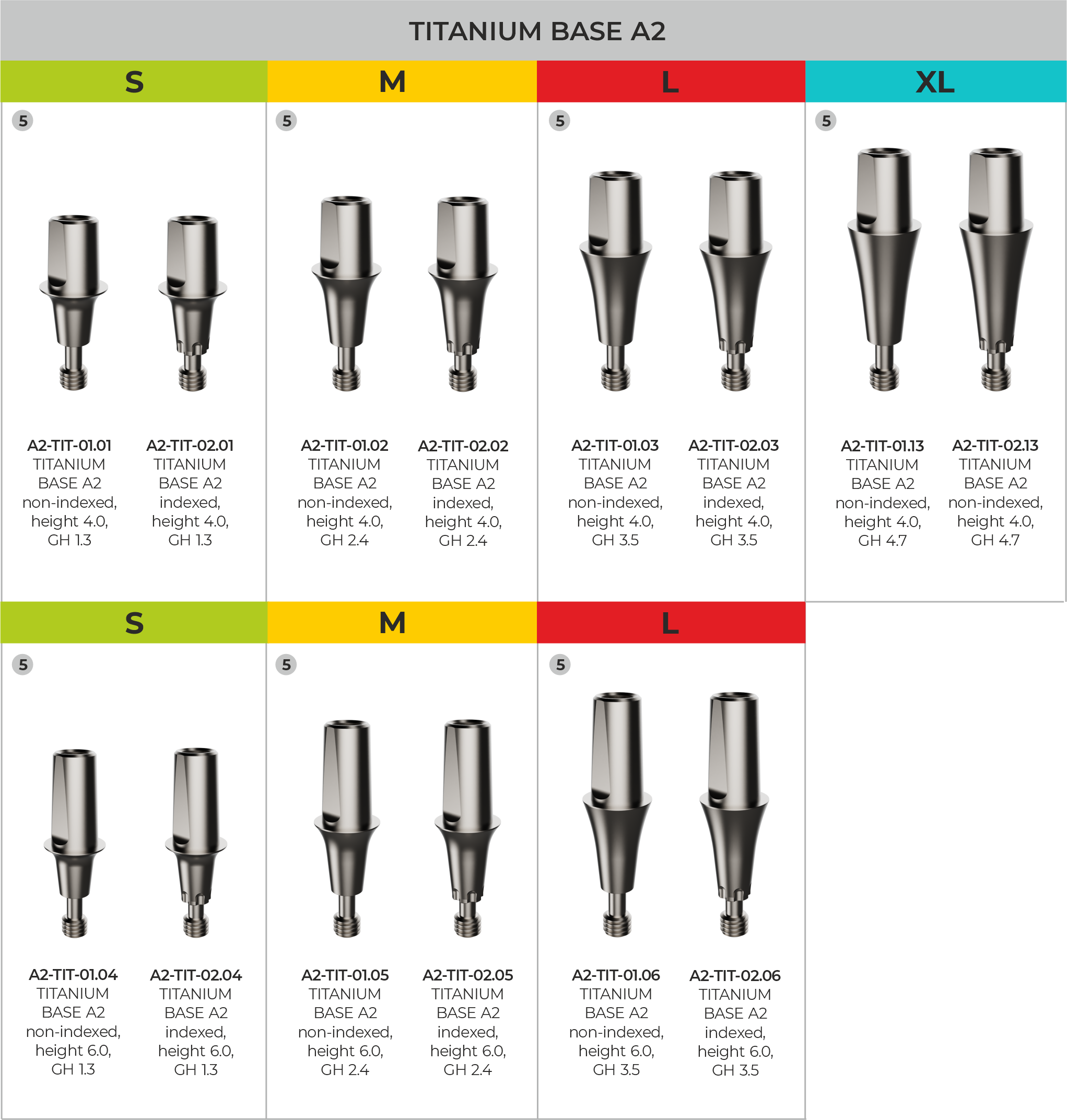

A2 TITANIUM BASES

INDICATIONS for use: single crowns with screw retention

- are simple and reliable suprastructures ideally for screw-fixed crowns.

- have an integrated screw to increase patient safety against aspiration: there is no need for placement and cannot fall out.

- offer a wide range heights of gingiva transition (S, M, L and XL) and supra-gingival parts (4.0 mm and 6.0 mm).

- can be downloaded from our website (A2implant.com) to create crowns in CAD programs.

- with an index can be easily seated in one of six positions.

- without an index, use a transfer key for proper positioning.

CAUTION: The manufacturing of bridges on A2 Titanium bases with screw fixation from the implant level is not recommended because of the risk of incomplete cone fit.

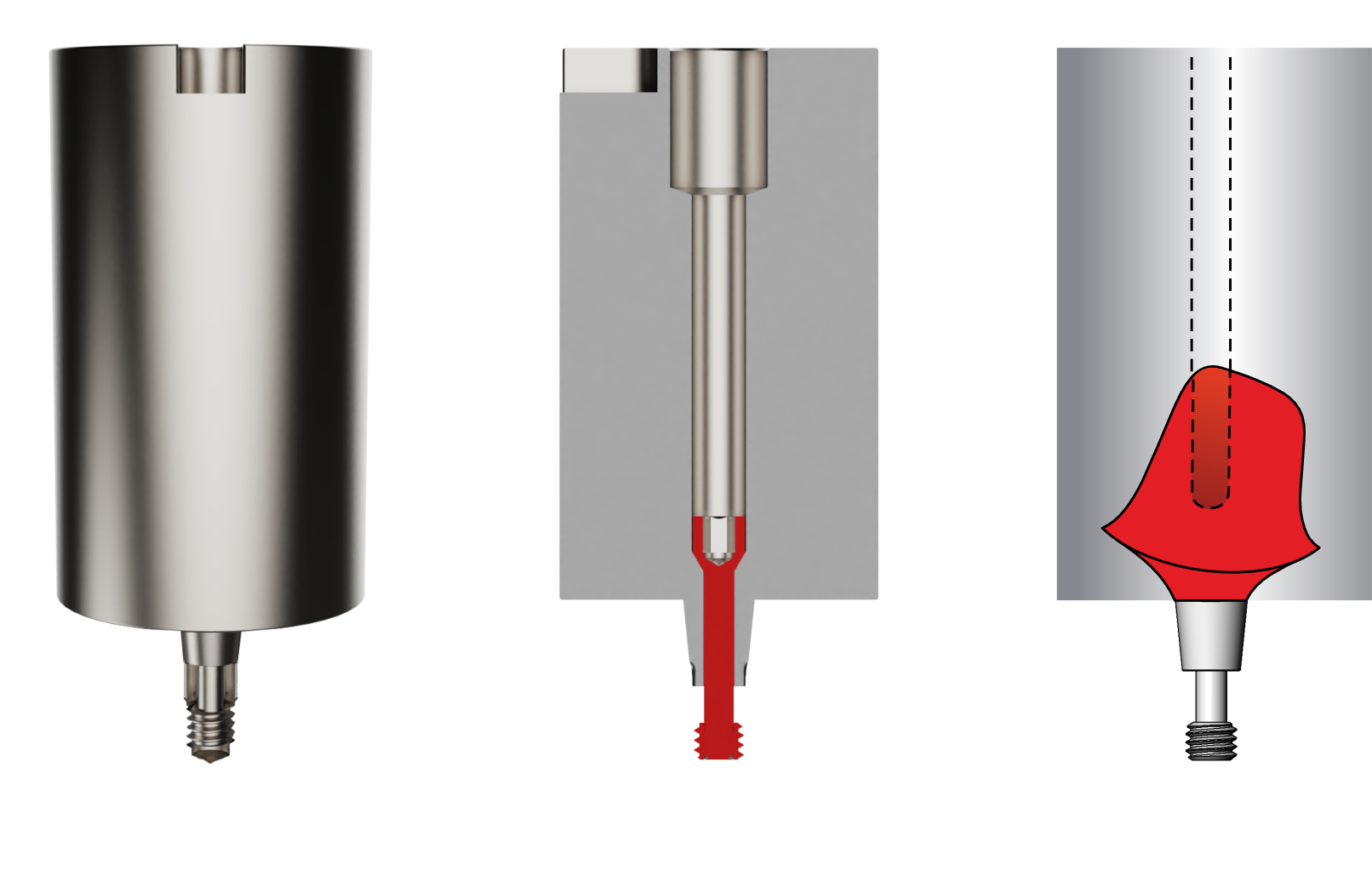

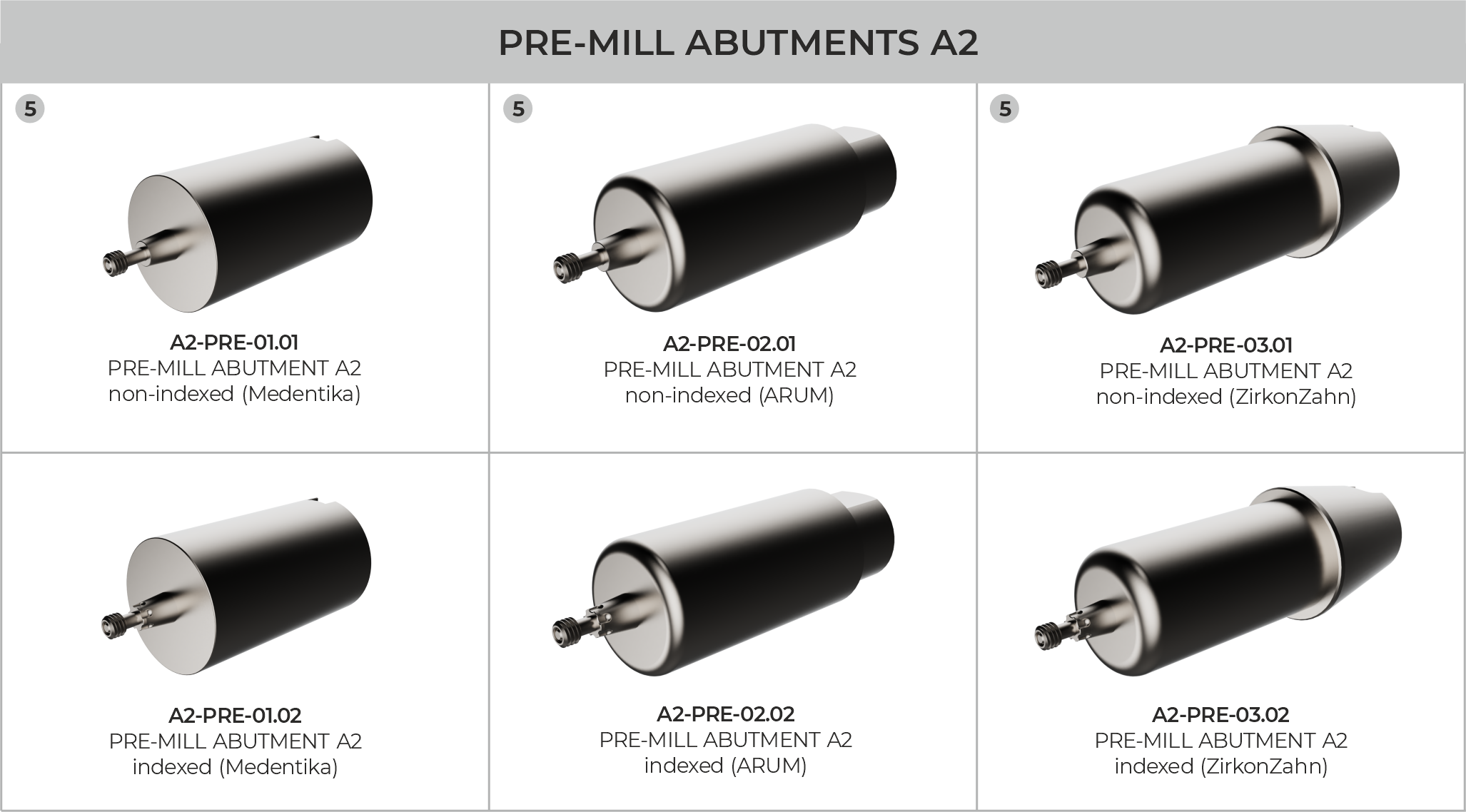

A2 PRE-MILL ABUTMENTS

INDICATIONS for use: crowns and bridges with cement or screw retention

- consist of one part that is precision-milled in the factory and one part that is milled in the dental laboratory to create a custom abutment.

- have an integrated screw to increase patient safety against aspiration: there is no need for placement and cannot fall out.

- can be downloaded from our website (A2implant.com) to design with CAD programs.

- provide sufficient initial dimension to create different gingival depths and angles of inclination.

- can be adapted for the following holders: Medentica / Arum / Zirkonzahn

- with an index can be easily seated in one of six positions.

- without an index, use a transfer key for proper positioning.

CAUTION: For reliable cement retention, the shortening should not be less than 4 mm.

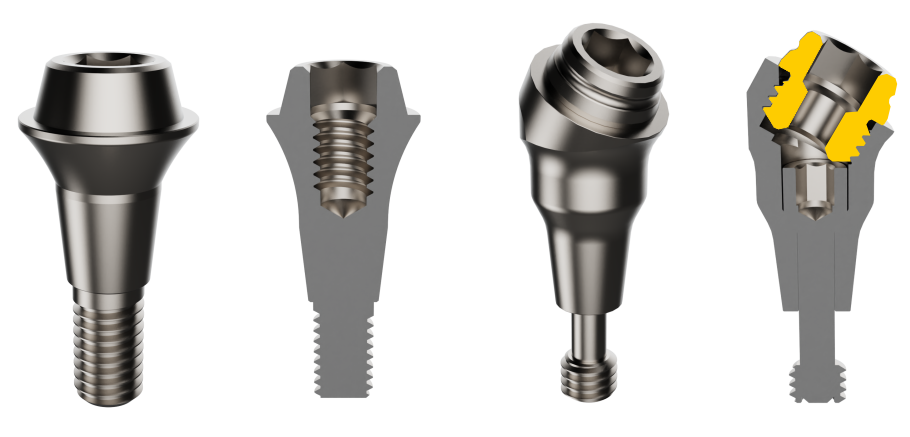

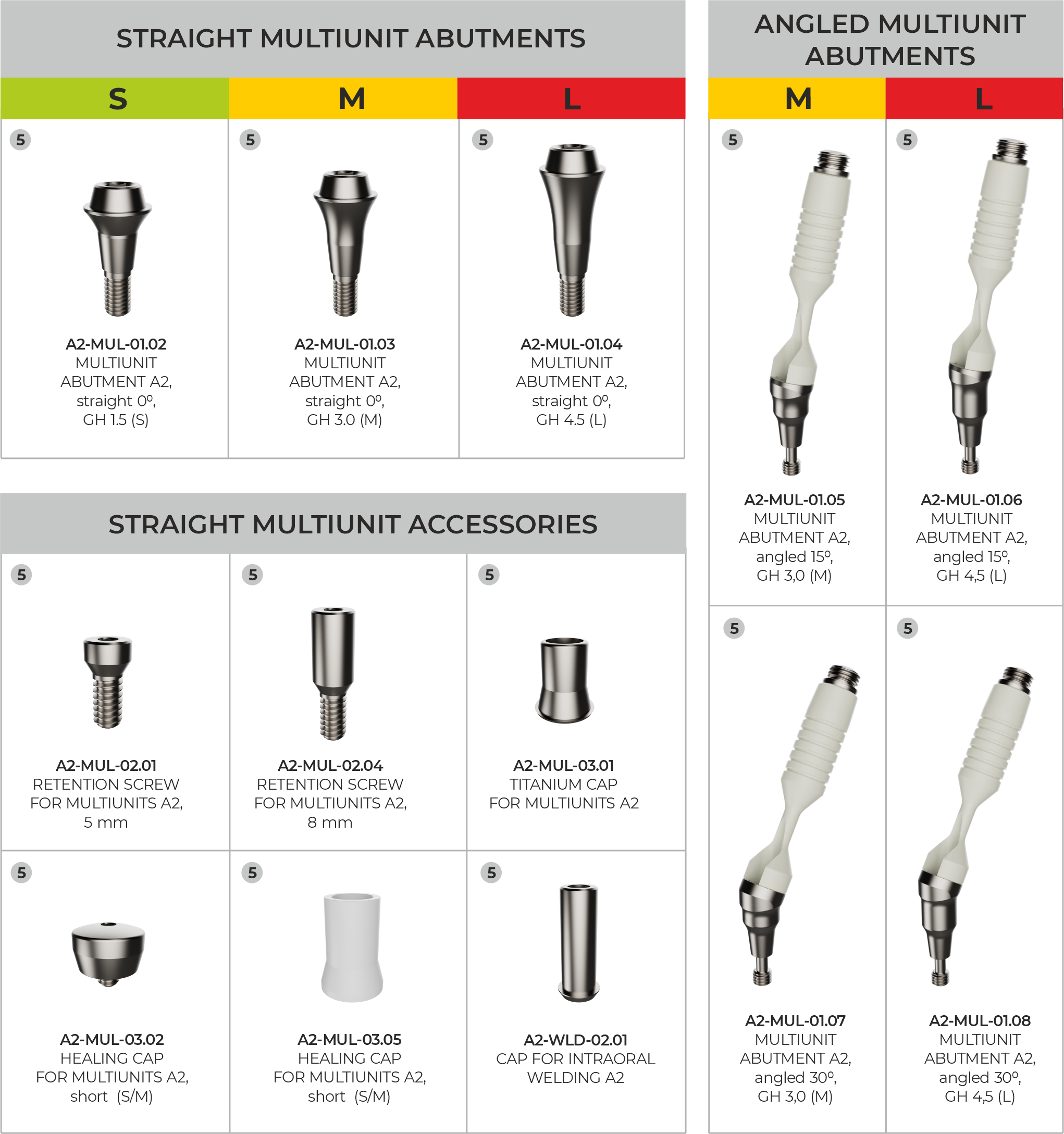

A2 MULTIUNIT ABUTMENTS

INDICATIONS for use: bridges with screw retention

- are designed for screw-retained bridges.

- offer a wide range of gingiva heights (S, M and L) an inclination angles (0°, 7.5° and 30°).

- are solid when straight, angled with integrated screw.

- can be downloaded from our website (A2implant.com) to create bridges in CAD programs.

- allow the use of A2 Titanium Caps, which provide a passive fit of the bridge and prevent the zirconia from cracking during fixation.

CAUTION: The fabrication of single crowns is contraindicated.

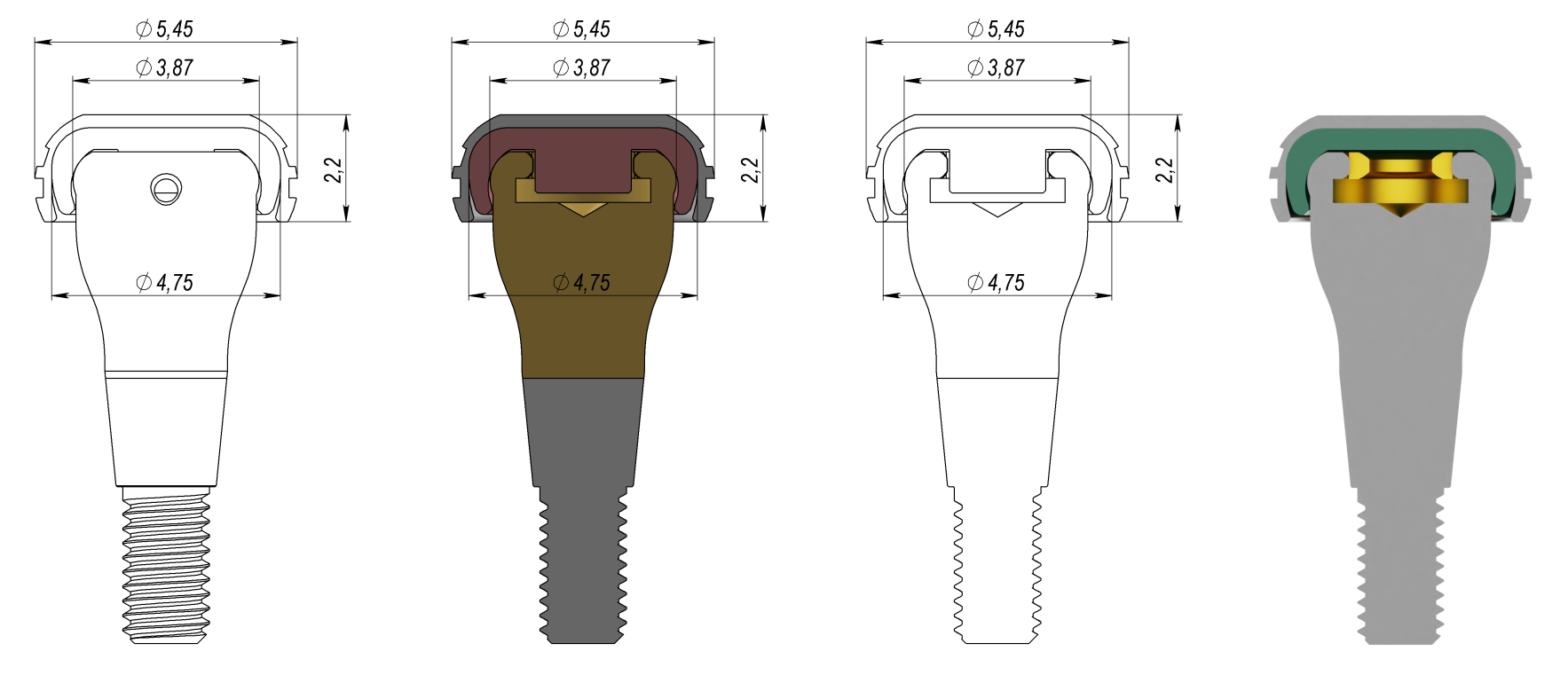

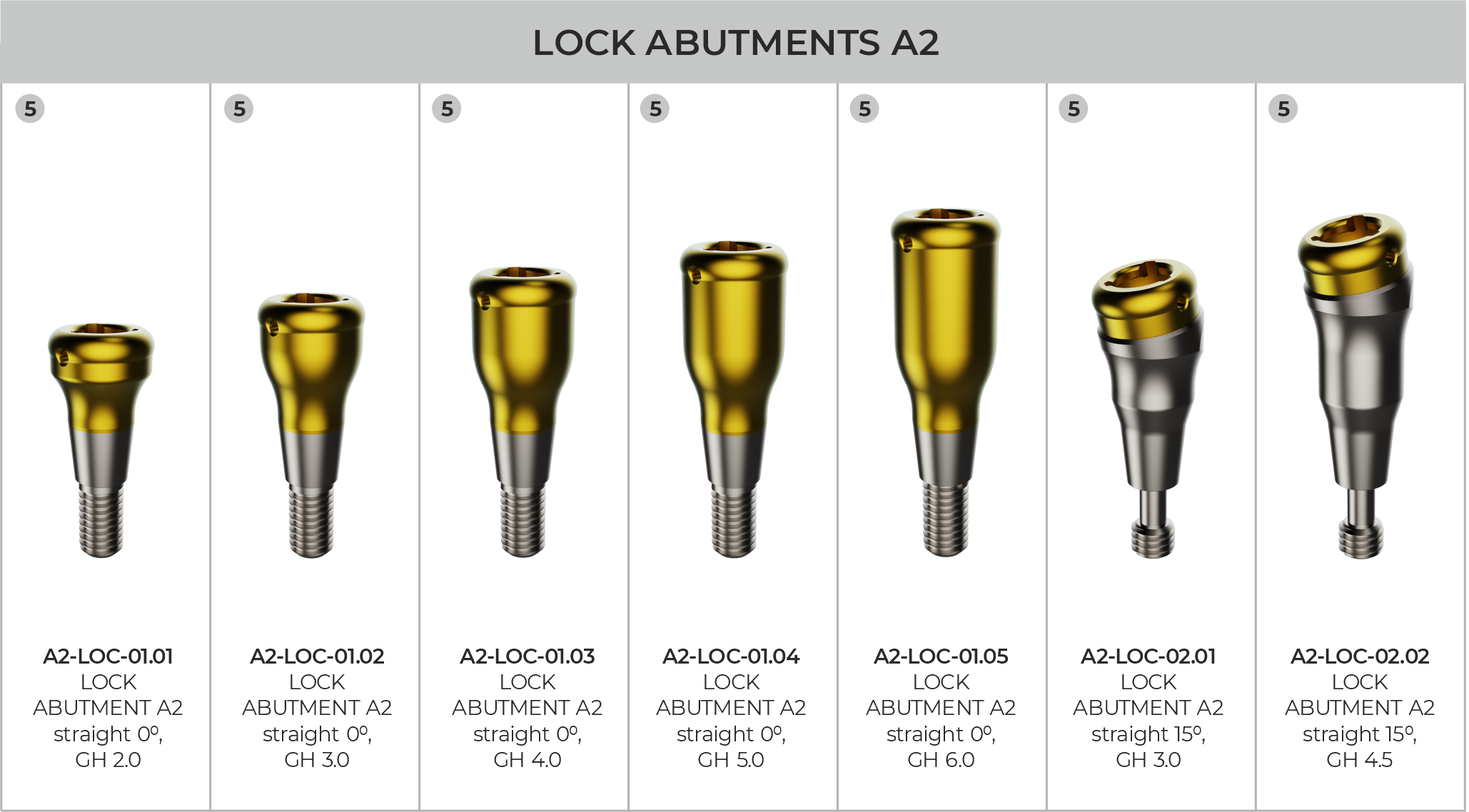

A2 LOCK ABUTMENTS

INDICATIONS for use: implant-retained tissue supported overdentures

- offer a wide range of gingiva heights (2 mm, 3 mm, 4mm, 5mm and 6 mm) an inclination angles (0° and 7.5°)

- have an universal upper cylindrical part

- are solid when straight, angled with integrated screw.

- use a titanium matrix with a nylon insert to anchor removable full dentures.

- with attached matrix require a minimum of 7.5 mm vertical space from the implant shoulder (2 mm gingival height + 3.5 mm attachment and 2 mm denture acrylic).

- with attached matrix require a minimum of 9.5 mm of space in the horizontal plane (5.5 mm matrix ø + 2.0 mm each of oral and buccal denture acrylic).

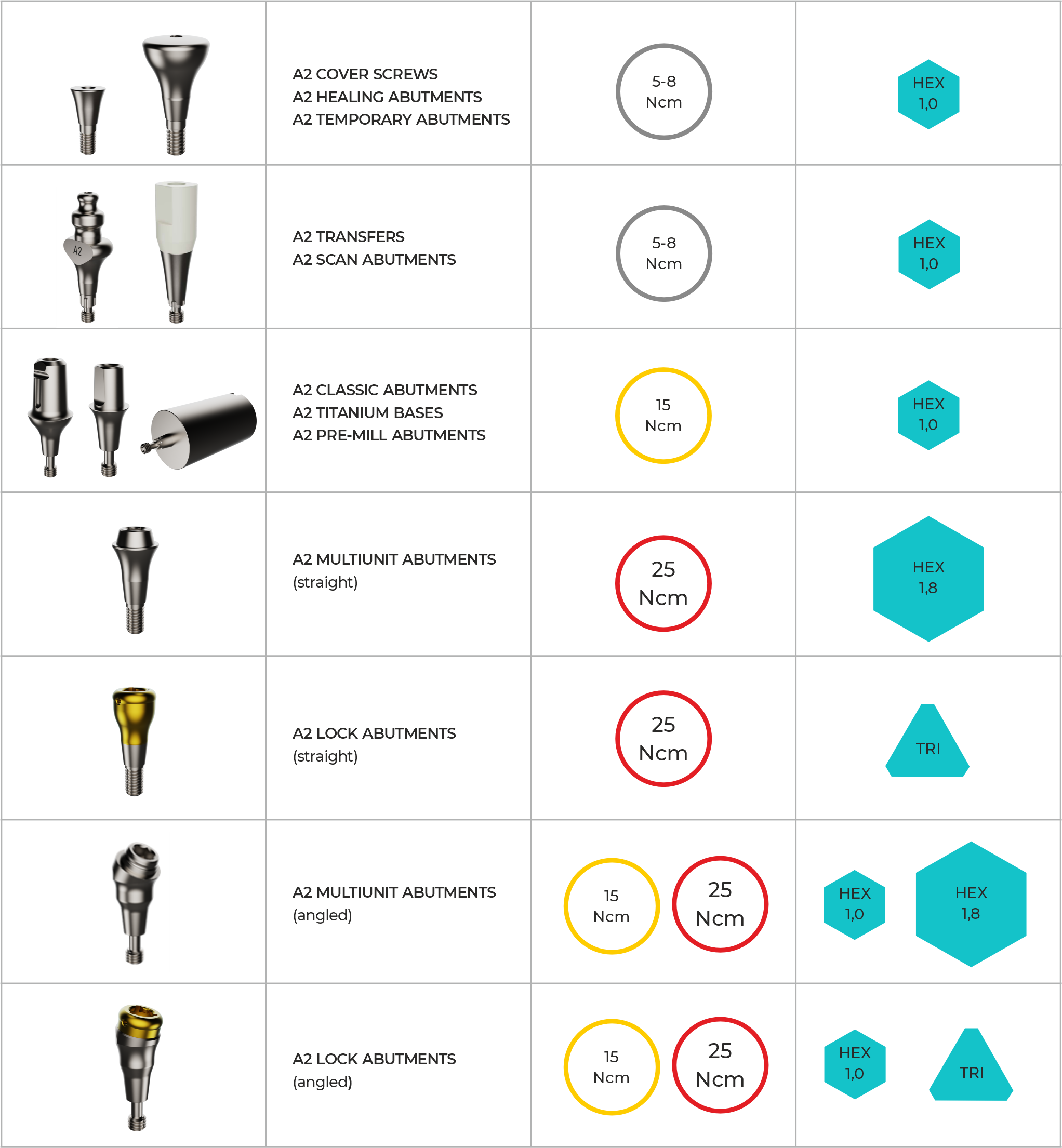

A2 PROSTHETIC INSTRUMENTS

- Cover Screws, Healing, Impression and Scan Abutments have a 7.0 mm hex slot. Use a manual 1.0 mm hex Screwdriver without excessive effort.

- Classic Abutments, Titanium bases and milled Blanks have a hex slot located in the cap of the integrated screw. Use a 1.0 mm hex Screwdriver and a prosthetic ratchet wrench to apply 15 Ncm of torque.

- Strait Multiunit Abutments have a 1.8 mm hex slot. Use a 1.8 mm hex Screwdriver and prosthetic ratchet wrench to apply 25 Ncm of torque.

- Angled Multi-Unit Abutments consist of two parts: an angled base with a 1.0 mm hex and a platform with a 1.8 mm hex. Attach the angled base using a 1.0 mm hex Screwdriver with a torque of 15 Ncm, then attach the multi-unit platform using a 1.8 mm hex Screwdriver with a torque of 25 Ncm, applied by the prosthetic ratchet.

- Strait Lock Abutments have a 1.8 triangular slot. Use a 1.8 mm triangular Screwdriver and prosthetic ratchet wrench to apply 25 Ncm of torque.

- Angular Lock Abutments consist of two parts: an angled base with a 1.0 mm hex, and a platform with a 1.8 mm triangular slot. Install the corner base with a 1.0 mm hex Screwdriver with a torque 15 Ncm, then fix the platform with a triangular Screwdriver with a torque of 25 Ncm, applied by the prosthetic ratchet.